The Precision Behind Installing a Shaft Bearing: How Nitrogen, Science, and Maintenance Come Together

Have you ever witnessed the intricate process of installing a shaft bearing on a yacht? It’s an impressive and highly technical procedure that feels almost like preparing for a space mission—one that requires precision, science, and years of engineering expertise. As we’re two weeks away from the sea trials for the second refit of Project R11, a 60m motor yacht undergoing extensive propulsion refits in 2024, let’s explore the critical steps behind the installation of a shaft bearing and why it’s an essential part of a yacht’s refitting process.

Why Bearings Are Critical for Yachts

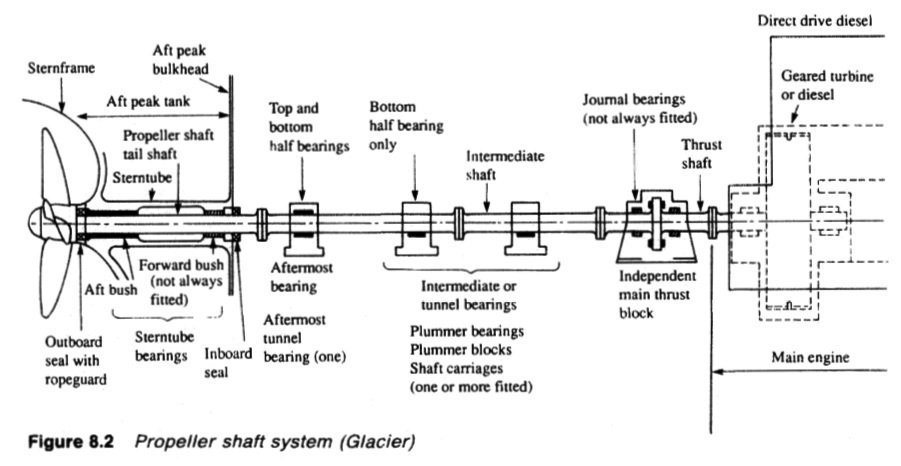

Shaft bearings play an essential role in ensuring the smooth operation of a yacht’s propulsion system. They support and guide the propeller shaft as it rotates at high speeds, minimizing friction and wear on the shaft itself. This allows the vessel to operate efficiently, without the risk of overheating or causing excessive vibration, which can lead to further mechanical issues.

But why do bearings need to be replaced as part of a regular refit, specifically after a five-year period? The answer lies in the intense wear and tear experienced by the bearings, especially in marine environments. Over time, bearings are subjected to saltwater corrosion, friction, and extreme pressure, all of which degrade their performance. Regular inspections, including penetration tests (nondestructive testing used to check for cracks or defects), help identify when a bearing has reached the end of its life cycle and requires replacement.

The Science Behind Installing a New Shaft Bearing

Replacing a bearing isn’t as simple as just removing the old one and putting in the new. It’s a process steeped in scientific principles, particularly when it comes to fitting the new bearing to the shaft. One of the most fascinating techniques involves the use of liquid nitrogen to cool the bearing.

When bearings are manufactured, they’re typically made slightly smaller than the shaft they’re designed to fit onto. This is where physics comes into play. By cooling the bearing with liquid nitrogen, the metal contracts, temporarily shrinking in size. This allows the bearing to easily slide onto the shaft without force. As the bearing returns to ambient temperature, it expands back to its original size, creating a perfect, tight fit around the shaft.

This method ensures that the bearing is securely seated without the need for excessive force, which could damage the bearing or the shaft. In scientific terms, this process leverages thermal contraction (from cooling) and thermal expansion (as it warms) to create an ideal and precise fit. The use of nitrogen is particularly critical for large-scale equipment like the propulsion systems of yachts, where precision is non-negotiable.

The Role of Nitrogen in Bearing Installation

Liquid nitrogen, with a boiling point of -196°C (-321°F), is the perfect tool for this application. The extreme cold causes rapid contraction of the bearing material, usually made from highly durable metals like steel alloys. Once cooled to this low temperature, the bearing becomes significantly smaller in diameter, making the installation process smoother.

Once fitted onto the shaft, as the bearing gradually warms to its normal operating temperature, the expansion locks it into place with high precision. This scientific method is highly reliable and helps ensure the longevity and performance of the new bearing.

The Importance of Shaft Bearing Replacement in Refitting

For a yacht like the 60m Project R11, which has undergone multiple propulsion refits during her 2024 visit, regular bearing maintenance is critical. Replacing the shaft bearing ensures optimal performance, reduces wear and tear on other propulsion components, and ultimately helps prolong the lifespan of the vessel. During refits, penetration tests are used to assess the condition of key components, including the bearings. If wear, cracks, or corrosion are found, replacement is necessary.

Every five years, as part of routine maintenance, yachts undergo comprehensive overhauls that include propulsion system checks. This is standard in the industry to ensure safety and efficiency. Refitting a vessel of this magnitude, including replacing the shaft bearing, guarantees that it’s ready for the high demands of marine operation.

Sea Trials

As Project R11 finished her sea trials, these propulsion updates and shaft bearing replacements are just part of a long list of upgrades aimed at restoring her to peak performance. These trials will be the ultimate test of the work done during the refit, evaluating everything from speed and efficiency to noise levels and overall functionality.

The success of this work hinges on attention to detail, careful planning, and the application of scientific methods—just like the precise bearing installation using nitrogen cooling. And once Project R11 passes her sea trials, she’ll be back in action, sailing smoothly with a propulsion system that’s been meticulously refitted for another round of adventures.

Stay tuned as we approach launch day for Project R11!